Trailer Axles

- Home

- Trailer Axles

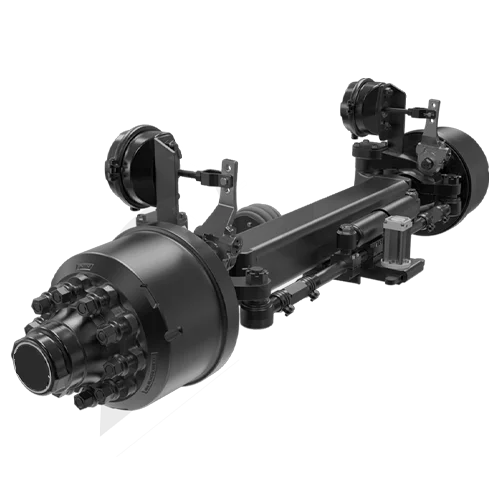

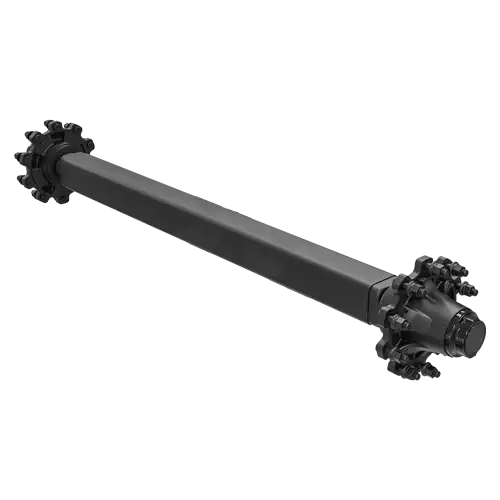

The Role of Trailer Axles in Load Transportation

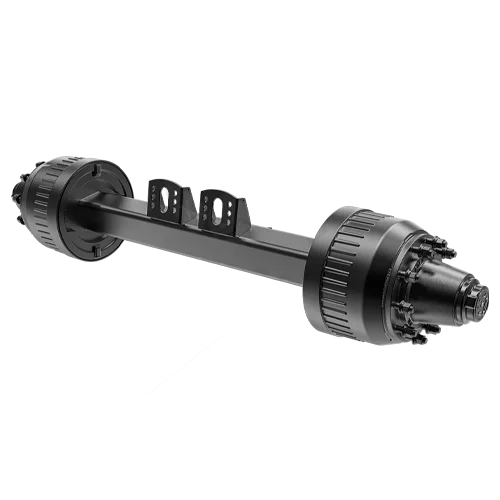

Trailer axles are fundamental components in the transportation industry, playing a crucial role in ensuring the safe, stable, and efficient movement of goods. These axles support the entire weight of the trailer and its cargo, directly impacting vehicle performance, fuel efficiency, and overall safety. A poorly selected or maintained axle can lead to mechanical failures, increased wear and tear, and potential road hazards. To avoid these issues, it is essential to carefully consider factors such as load capacity, material strength, and suspension type when choosing a trailer axle.

In commercial and industrial transportation, selecting the right axle can improve durability and reduce operational costs. Whether used for light-duty trailers or heavy-haul transport, axles must be chosen based on the specific requirements of the application. Advanced axle systems designed with high-quality materials and modern engineering techniques can extend the lifespan of trailers while ensuring smoother and more reliable operation.

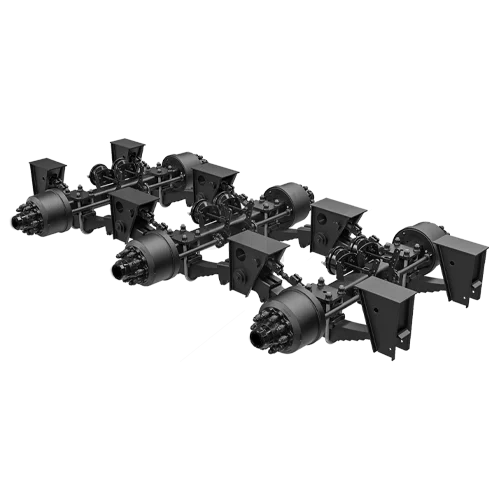

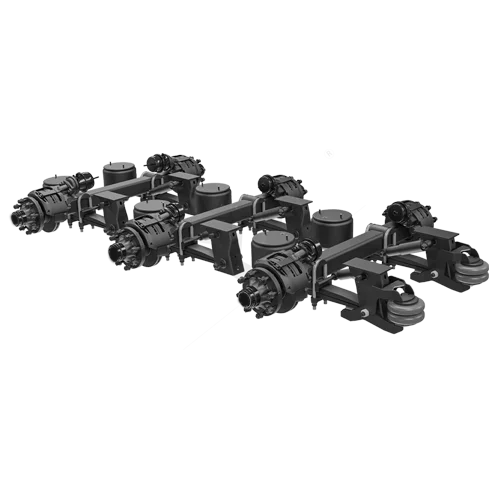

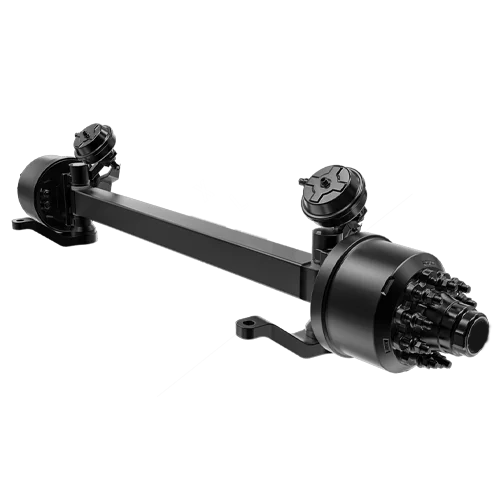

Types of Trailer Axles and Selection Criteria

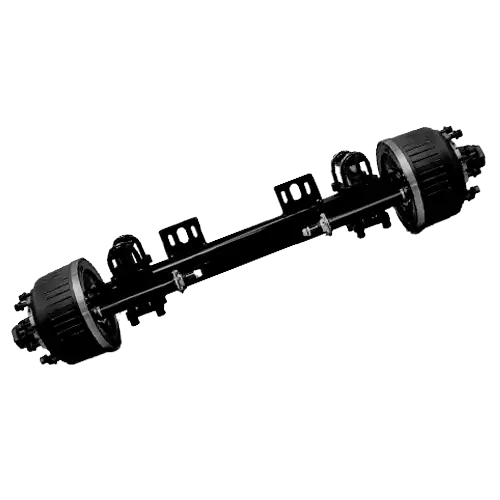

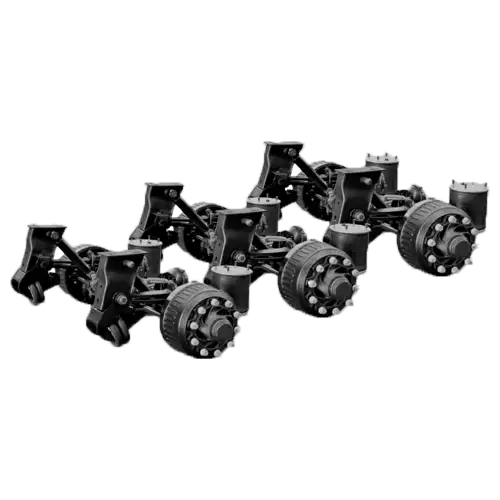

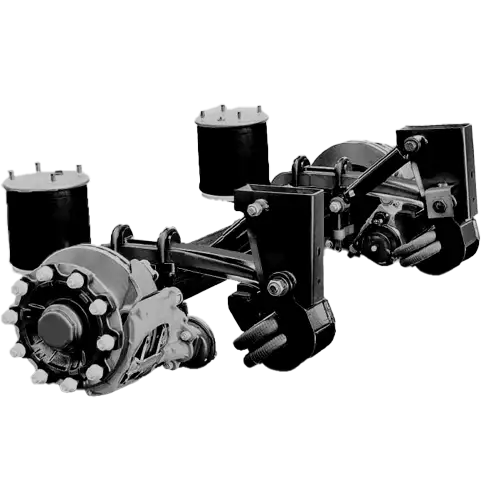

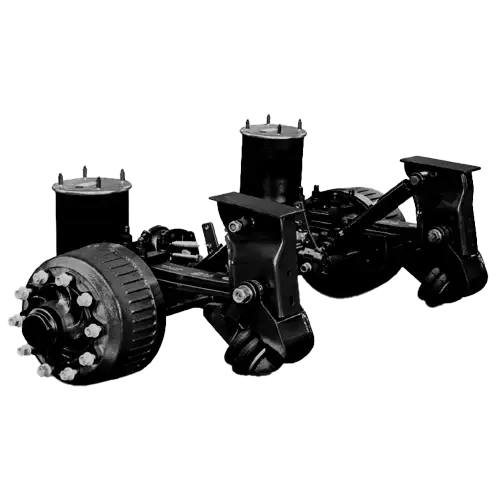

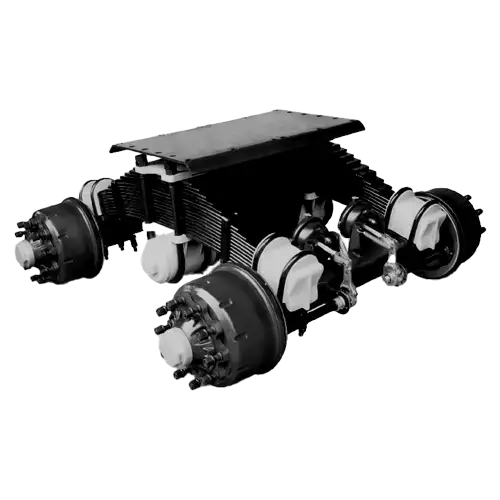

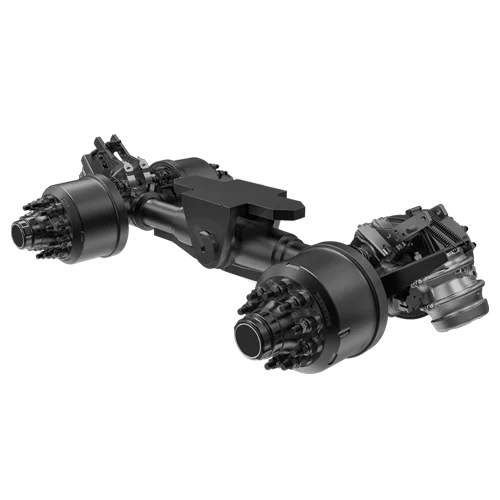

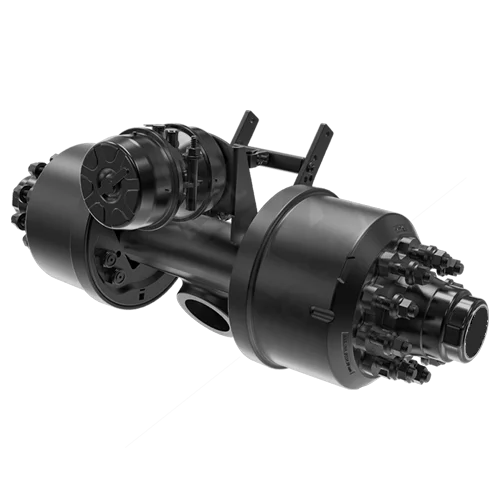

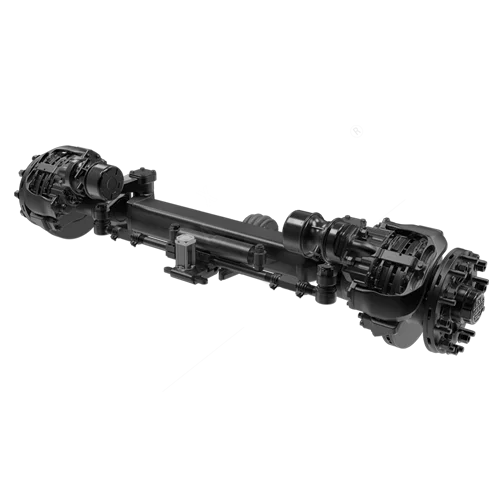

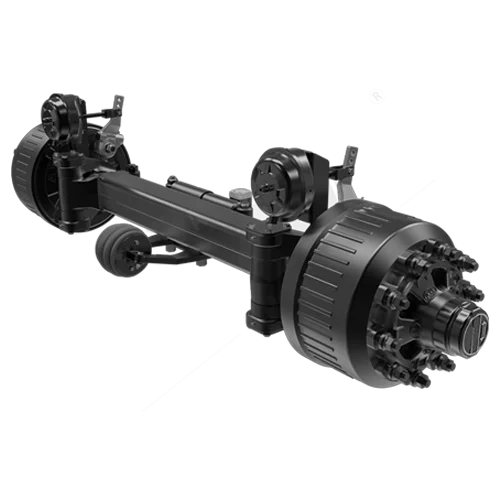

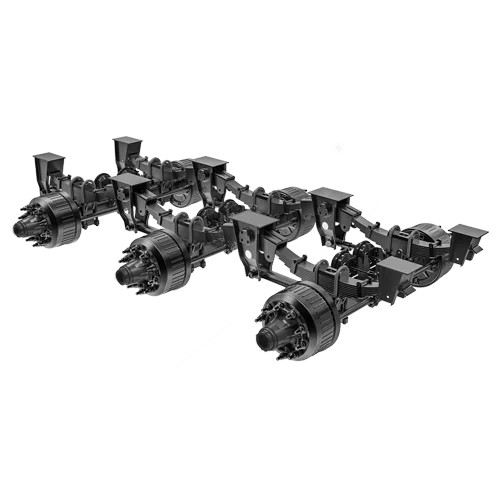

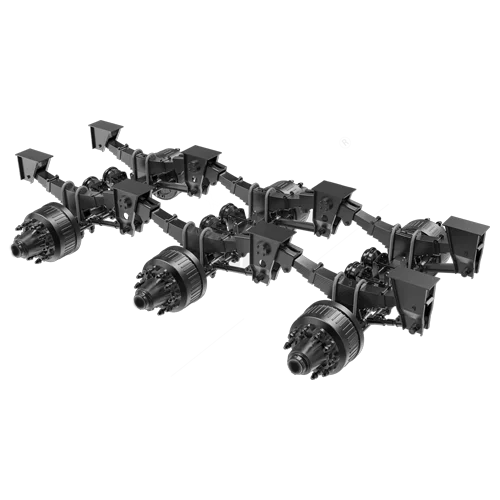

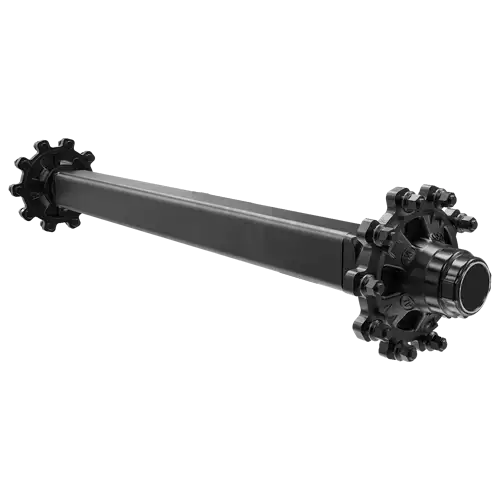

There are several types of trailer axles, each designed for different purposes. Fixed axles, the most commonly used type, are ideal for standard transportation and provide a stable foundation with minimal maintenance requirements. Steerable axles offer greater maneuverability, making them suitable for vehicles that need to navigate tight spaces, such as urban delivery trucks or specialized transport units.

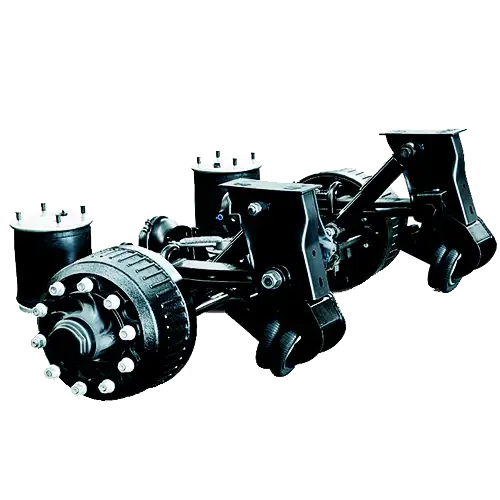

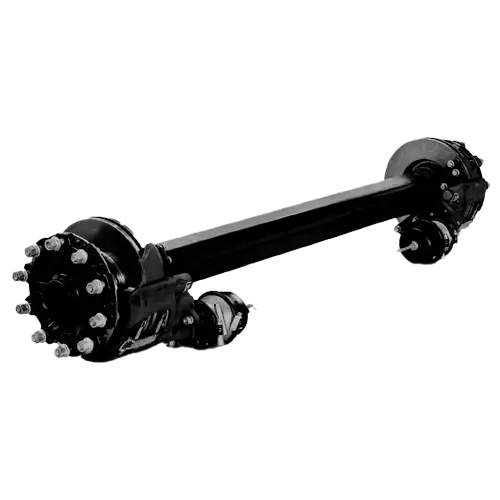

For those prioritizing comfort and cargo protection, air suspension axles are an excellent choice, as they reduce vibrations and improve load stability, making them ideal for transporting fragile or high-value goods. In contrast, low-profile axles are specifically designed for carrying heavy loads, offering enhanced weight distribution and improved safety on long-haul routes.

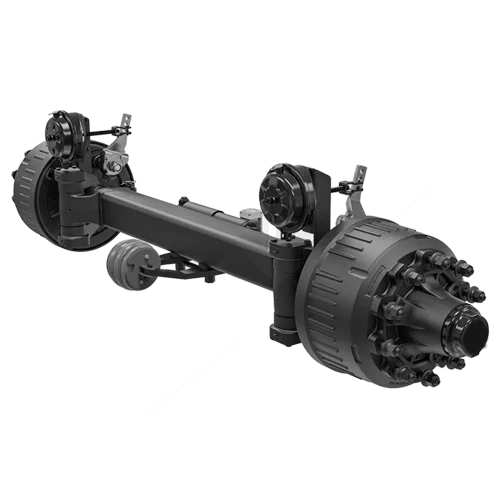

Material selection is another important factor when choosing an axle. Steel axles are known for their exceptional strength and durability, making them well-suited for heavy-duty applications. However, aluminum axles provide a lightweight alternative, helping to reduce fuel consumption and increase overall efficiency. The choice between steel and aluminum depends on factors such as load weight, operating environment, and maintenance preferences.

The Importance of Maintenance and Tips for Longevity

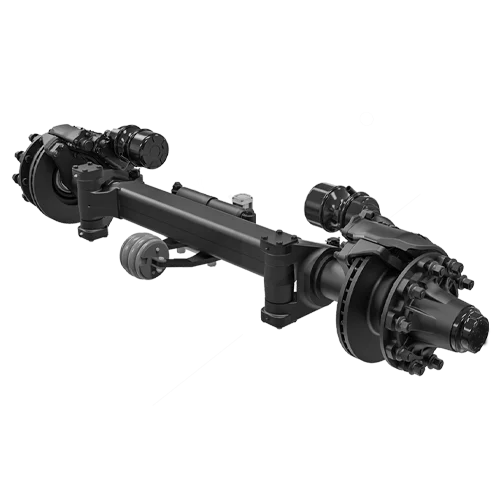

To maximize the lifespan and efficiency of trailer axles, regular maintenance is essential. One of the most critical aspects of axle maintenance is lubrication. Proper lubrication reduces friction between moving parts, preventing premature wear and increasing the overall efficiency of the axle system. Bearings should also be inspected periodically, as they play a vital role in ensuring smooth wheel rotation and load distribution.

Early detection of damage, rust, or misalignment can prevent costly repairs and reduce the risk of mechanical failure. Routine inspections should include checking the axle housing, suspension components, and braking system for signs of wear. Ensuring compatibility between the axle and braking system is particularly important, as it directly affects vehicle control and safety.